振动筛

我公司生产的ZDS系列直线振动筛具有稳定可靠、消耗少、噪音低、寿命长、振型稳、筛分效率高等优点。主要用于磨料磨具原料、化工、塑料、医药、树脂粉、陶瓷原料、冶金、建材、粮食、化肥等行业中的干式粉状、细颗粒状或细微粉物料的筛分。

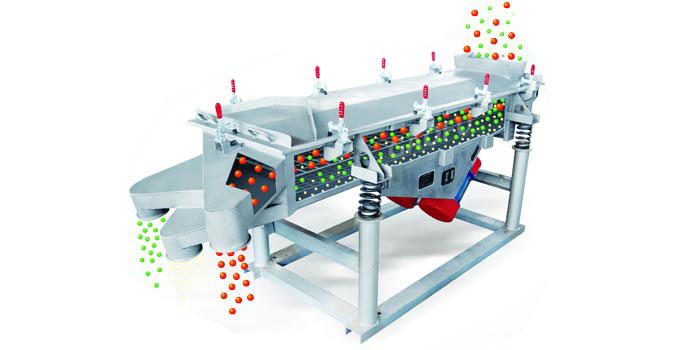

ZDS系列直线振动筛工作原理

ZDS系列直线振动筛采用双振动电机驱动,当两台振动电机做同步、反缶旋转时,其偏心块所产生的激振力在平行于电机轴线的方向相互抵消,在垂直于电机轴的方向叠为一合力,因此筛机的运动轨迹为一直线。其两电机轴相对筛面有一倾角,在激振力和物料自重力的合力作用下,物料在筛面上被抛起跳跃式向前作直线运动,从而达到对物料进行筛选和分级的目的。可用于流水线中实现自动化作业。具有能耗低、效率高、结构简单、易维修、全封闭结构无粉尘溢散的特点。最高筛分目数325目,可筛分出7种不同粒度的物料。

ZDS系列直线振动筛主要特点

1.该型筛分机适合高产能的粗分作业。

2.该料在筛面上行程长,处理量大。

3.筛选的同时,对物料进行平行输送。

4.可调整筛面倾角,来平衡透筛精度的生产量。

2.该料在筛面上行程长,处理量大。

3.筛选的同时,对物料进行平行输送。

4.可调整筛面倾角,来平衡透筛精度的生产量。

主要技术参数

| 型号 | 筛面尺寸 | 筛面层数 | 网孔尺寸 | 处理量 | 振次 | 双振幅 | 电机功率 | 振动方向角 | 外形尺寸(长×宽×高) |

|---|---|---|---|---|---|---|---|---|---|

| ZDS520 | 1 / 2 / 3 / 1 / 2 / 3 / 4 / 5 / 6 | 2–200 | 0.05–5 | 960 | 6–7 | 2×0.4 | 45–60 | 2140×808×848 | |

| 2ZDS520 | 500×2000 | 0.05–5 | 960 | 6–7 | 2×0.4 | 45–60 | 2199×808×878 | ||

| 3ZDS520 | 500×2500 | 0.03–5 | 1450 | 4–6 | 2×0.4 | 45 | 2256×808×938 | ||

| ZDS525 | 0.06–8 | 960 | 5–7 | 2×0.4 | 45–60 | 2642×808×848 | |||

| 2ZDS525 | 0.06–8 | 1450 | 4–6 | 2×0.4 | 45 | 2699×808×878 | |||

| 3ZDS525 | 0.06–8 | 960 | 6–8 | 2×0.75 | 45–60 | 2750×808×938 | |||

| 4ZDS525 | 0.1–15 | 1450 | 5–7 | 2×0.4 | 45 | 2813×808×1000 | |||

| 5ZDS525 | 0.08–15 | 1450 | 5–7 | 2×0.4 | 45 | 2883×808×1060 | |||

| 6ZDS525 | 0.07–15 | 960 | 6–8 | 2×0.75 | 45–60 | 2953×808×1120 |